Maury Microwave in Numbers

Here are a few numbers we are proud of.

66+ Years

40+ Countries

6k+ Tuners

15k+ Inventory

Confidence in Measurements & Models

Our mission is to give our customers confidence in their RF through THz measurements and models. We accomplish this by providing best-in-class and fully-proven characterization solutions, components and services. We help the world’s leading manufacturers in the wireless technology chain build better products and bring them to market faster.

Product Lines

Leverage our best-in-class solutions to increase confidence in your measurements and models.

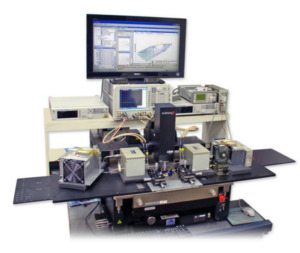

Device Characterization Solutions

Industry-leading measurement and modeling device characterization software, active load pull systems, impedance tuners, pulsed bias systems and system accessories.

Amplifiers

Our amplifiers combine cutting-edge load pull technology and application expertise to bring you the best amplifier solutions for your applications.

Precision Calibration Solutions

VNA calibration and validation are the cornerstone of accurate and repeatable measurements. Our solutions incorporate uncertainties to enhance confidence in your measurements.

Interconnect Solutions

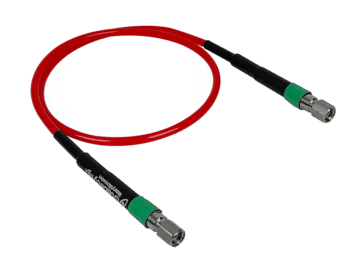

Cable assemblies, adapters, attenuators and tools purpose-designed to reduce your measurement uncertainties and improve measurement accuracy and repeatability.

Best-In-Class Solutions

Examples of our best-in-class device characterization solutions

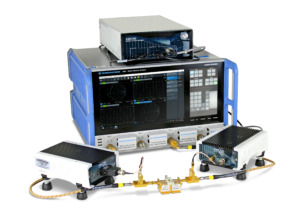

The MT2000 is an absolute game-changer for my research. It provides lightning-fast active harmonic load-pull and modulated signal measurements of devices. This sheds light on the true operation of the devices under test in realistic operating conditions.

Associate Professor of Engineering

A prestigious US university

We currently uses a passive vector-receiver based load-pull system developed Maury Microwave. Our experience has shown that the Maury hardware and software are able to accurately measure and extract small and large signal models which we can then use to develop our core MMIC designs with a high success rate.

Director of Engineering

A company that designs custom microwave and mmW subsystems for the defense market

Since 2006 I’ve been active in the field of load-pull and the characterization of high power devices, such as GaN and LDMOS and for two different companies. Along my ways I’ve found in Maury MW a highly reliable partner. Their automated impedance tuners and their load-pull software have set a standard for the industry.

RF Characterization Engineer

A global semiconductor manufacturer

Our load-pull bench is an indispensable tool for the on-wafer characterization of GaN HEMTs. The bench is entirely controlled by Maury's software and facilitates X-band power measurement through the third harmonic and permits dynamic load-line extraction and analysis. We probe our devices on-wafer, accurately presenting reflection coefficients through Gamma=0.85.

Researcher

An Ivy League university

Partners

Through partnerships we have been able to best support our customers with the largest offering of best-in-class and fully validated solutions

Maury Microwave News

Learn what’s new at Maury.

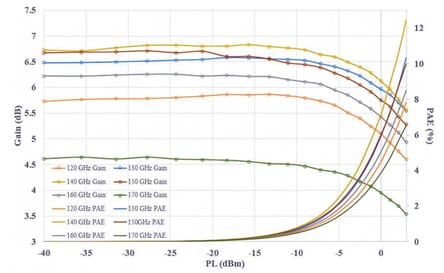

Millimeter Wave and Sub-THz Power Sweep and Active Load-Pull Measurements

Benchmarking a High Electron Mobility Transistor Using an Active Load-Pull System at 120 GHz–170 GHz

New High Frequency Diplexers for Active Load Pull

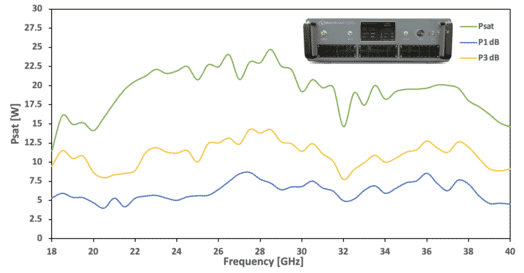

New Broadband 18-40 GHz 10W, 20W and 40W Amplifiers for T&M and EMC

Maury Microwave and National Physical Laboratory (NPL) Join Forces to Advance Cryogenic Measurement Capabilities for Quantum Computing

Overcoming the Challenges of Passive On-Wafer Load Pull Measurements at Millimeter Wave Frequencies for 5G Applications

QuickTest™ Push-On Pull-Off Adapters Now to 50 GHz!

Maury Hires New CEO: Sathya Padmanabhan

New SMA Screw-On Gages

StabilityFlex™ Ultra-Flexible Cable Assemblies Now to 50 GHz!

Company Culture

We are committed to fostering a workplace culture that not only embraces diversity, innovation, and collaboration but also puts people at the heart of everything we do.

We’d love to hear from you!

Feel free to contact us for more information, to speak with a salesperson, to access support on a Maury product, or to say hello.